I had the opportunity of visit a print site, somewhere in the deepest darkest most inequitable parts of east london. I was living the real life “how its made”, sadly without the music.

Starting out.

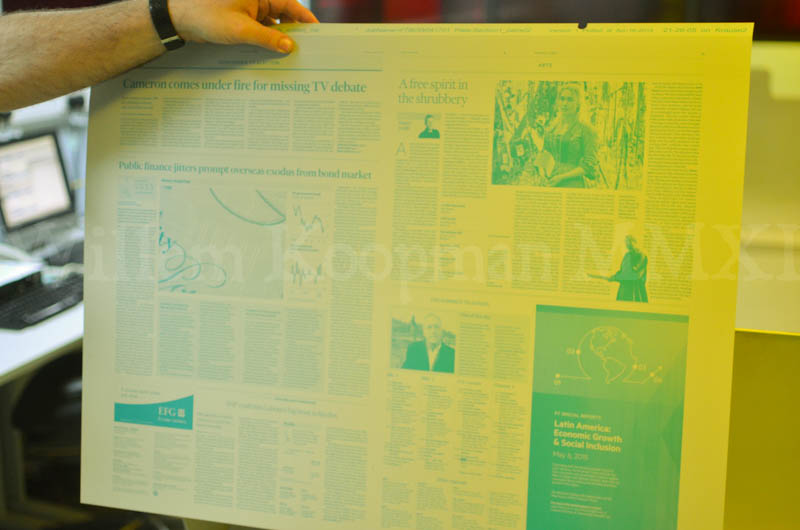

The paper is delivered to the printers as a PDF. This file is split up into the 4 constituent colours: Black, Cyan, Magenta and Yellow. Each colour is then Lasered onto a sheet of aluminium:

The blue colour is the light sensitive ink which is washed off to reveal a positive image:

This plate is formed into half a cylinder and paired with another page. There are high precision holes in the aluminium to allow minute adjustments. As this is an offset print process, the ink is applied to the plate, the plate then transfers it to a rubber cylinder, which in turn smears the image onto the paper.

This plate is formed into half a cylinder and paired with another page. There are high precision holes in the aluminium to allow minute adjustments. As this is an offset print process, the ink is applied to the plate, the plate then transfers it to a rubber cylinder, which in turn smears the image onto the paper.

The plates are installed into a machine called a stack:

The colours are stacked vertically, and both sides are printed at the same time. This printer effectively prints four pages at once.

The colours are stacked vertically, and both sides are printed at the same time. This printer effectively prints four pages at once.

Making sure that the colours are aligned, and the right amount of ink is applied is a highly skilled job. Every time a new page is printed, the plates must be aligned, and colours adjusted. This can eat through a lot of paper. Each print stack is controlled by a console like this:

Which is basically the coolest thing know to science. The console can control the rotational alignment around 0.001mm. At 30MPH.

Which is basically the coolest thing know to science. The console can control the rotational alignment around 0.001mm. At 30MPH.

the paper is fed into the print stack from massive 750kg toilet rolls:

The white strips is double sided sticky tape. When the top roll runs low, the bottom roll spins up and slams into the almost empty roll. At 30MPH.

The white strips is double sided sticky tape. When the top roll runs low, the bottom roll spins up and slams into the almost empty roll. At 30MPH.

Once the printed paper has escaped the print stack, it needs to be cut and folded: (this is an extraordinary cool machine, but I couldn’t get a decent picture)

Which then spits out sections like this:

Which then spits out sections like this:

Which we can then scoop out and have a look at for QC:

Which we can then scoop out and have a look at for QC:

A video of the paper transport in action:

A video of the paper transport in action:

The finished sections are rolled up and stored ready for combining into the finished newspaper: